What is DTF printing? Explore its working principle

Release time:

2025-07-19

Do you want to expand your product line with vivid, realistic and long-lasting printing effects? If you have this need, then you've come to the right place.

Currently,DTF printing is one of the most common technologies in the printing industry.

Most printing methods are limited to some similar fabrics, such as cotton and cotton blends. However, DTF printing can handle some more durable fabrics, such as polyester, wool, nylon, and of course, classic cotton.

What is DTF printing?

DTF printing involves applying patterns using water-based ink and special adhesive powder onto PET film (a special coated film that facilitates pattern transfer). Subsequently, the patterns on the PET film are heat-transferred onto the fabric using a hot press machine. This printing method is long-lasting, with rich pattern details and vibrant colors.

How does DTF printing work?

Compared with other printing methods, DTF has a very fast printing speed. It is also a good choice for printing fine patterns on thick outdoor clothing.

Do you want to know how it works? Let's take a closer look at the DTF printing process.

Step 1: Prepare the film

First, prepare a PET film and place it in the DTF printer. Print the entire pattern in color.

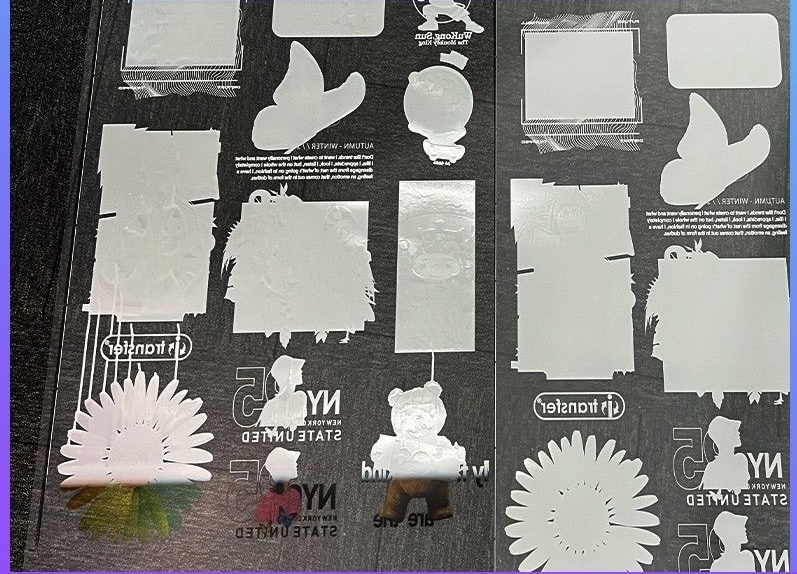

After creating the first layer, the machine will print a layer of white over the entire image, completely covering the first layer. If you are curious about the effect of the DTF printed pattern on the PET film, please see the following photos.

Next, evenly apply the adhesive powder onto the wet ink. After applying the powder evenly and removing the excess powder, heat the film and prepare for fabric transfer. The adhesive heating can be done in a curing oven or a hot press.

Step 2: Pre-press the fabric and use a hot press machine

After preheating the PET film, the patterned fabric is subjected to dehumidification and pre-pressing to achieve flatness under the hot press machine.

After the initial flattening, the printing film is placed on the pre-pressed fabric. Then, using the hot press machine, it is heated at an average temperature of 160°C for 8 to 10 seconds to transfer the pattern on the printing film onto the garment.

Step 3: Remove the film and perform post-pressing on the fabric

After transferring the pattern onto the fabric, the second-to-last step is to carefully heat-strip the film. Unlike cold-strip transfer printing, heat-strip transfer printing removes the film immediately while it is still hot - this is how Printful does it (and it is the stripping method used by most other DTF printing service providers).

After removing the film, the designed fabric will be pressed flat again in the heat press machine to enhance the durability of the pattern. After the heat press process, the clothing can be packaged and shipped to the customers.

Keyword:

RECENT POSTS