What is UV printing? Explore its workflow and applications

Release time:

2025-08-08

UV printing is a digital printing technology that uses UV-curable ink and ultraviolet (UV) light sources to achieve instant drying. The core principle is that the ink rapidly cures (changes from liquid to solid) upon contact with the substrate through the irradiation of UV lamps, thus completing the printing process. This technology is widely used in advertising, packaging, decoration and other fields due to its features such as rapid drying and wide applicability to materials.

In UV printing, UV ink and UV light are indispensable because they work together to provide accuracy and durability.In UV printing, UV ink and UV light are indispensable because they work together to provide accuracy and durability. UV ink is specially designed to remain liquid until exposed to ultraviolet light. UV ink is specially designed to remain liquid until exposed to ultraviolet light. During the printing process, the ink used is exposed to ultraviolet light, which immediately hardens it, allowing text to be printed on various surfaces without being absorbed. During the printing process, the ink used is exposed to ultraviolet light, which immediately hardens it, allowing text to be printed on various surfaces without being absorbed. This process ensures that the image is clear and colorful during capture and eliminates blurring. This process ensures that the image is clear and colorful during capture and eliminates blurring. Due to the fast curing speed, high efficiency of ultraviolet light and the reduction of materials used, productivity increases rapidly, proving that UV printing is an environmentally friendly choice for many businesses. Due to the fast curing speed, high efficiency of ultraviolet light and the reduction of materials used, productivity has increased rapidly, proving that UV printing is an environmentally friendly choice for many businesses.

Main features of UV printing

Wide range of applicable materials: It can be printed on various hard or soft materials such as paper, plastic, glass, metal, wood, stone, leather, etc., eliminating the strict requirements of traditional printing for the "wetability" of the substrate.

Fast drying speed: UV ink dries instantly, allowing for immediate stacking or subsequent processing (such as cutting, coating) after printing, significantly improving production efficiency.

Strong color expression: After ink curing, the colors are bright, highly saturated, and do not fade easily.

Good environmental performance: UV ink does not contain volatile organic compounds (VOCs), has no pungent smell, and poses less harm to the environment and human body.

Special effects can be achieved: such as raised texture, matte texture, local UV light oil highlighting, etc., enhancing the visual and tactile experience of the printed products.

Applications of UV Printing

Advertising field: billboards, light boxes, display boards, acrylic signs, etc.

Packaging industry: exquisite printing of gift boxes, cosmetic boxes, food packaging boxes, etc.

Decorative building materials: pattern printing on wooden floors, tiles, glass facades.

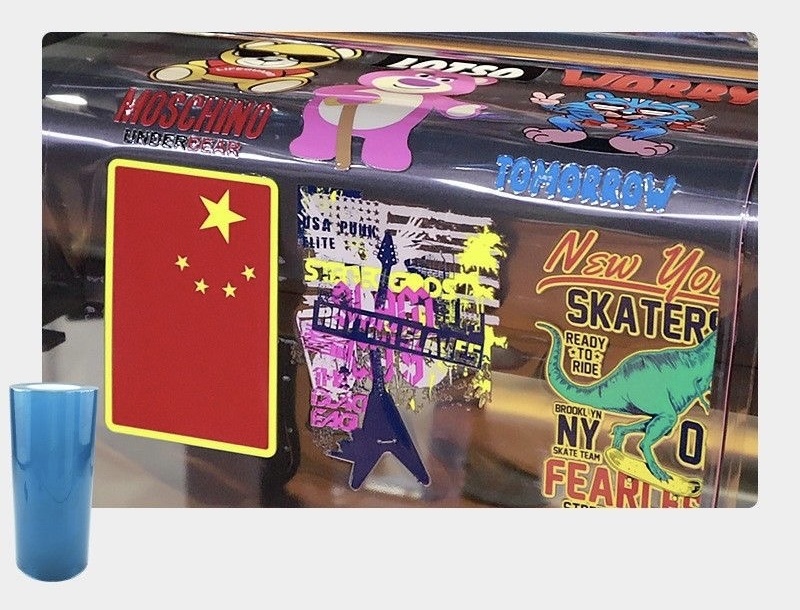

Personalized customization: custom pattern printing of small items such as phone cases, T-shirts, mouse pads, etc.

In summary, UV printing, with its advantages of high efficiency, environmental friendliness, and wide applicability, has become an important technology in the digital printing field, meeting diverse printing needs.

Keyword:

RECENT POSTS