FD61916 helps you quickly and reliably complete bulk order delivery!

Release time:

2026-01-04

| In the production of large-scale orders such as those in the clothing and home textile industries, as well as in advertising and decoration, do you often encounter such problems? The production efficiency fails to keep up with the pace of the orders. The color reproduction is always a little off. Frequent equipment maintenance affects the delivery... |

Today, we recommend to you an industrial-grade digital printing equipment specifically designed for efficient production - the FEDAR FD61916E digital printing machine. With its five core advantages, it redefines what "the perfect combination of efficiency and quality" means.

Part.1 Excellent quality, what you see is what you get

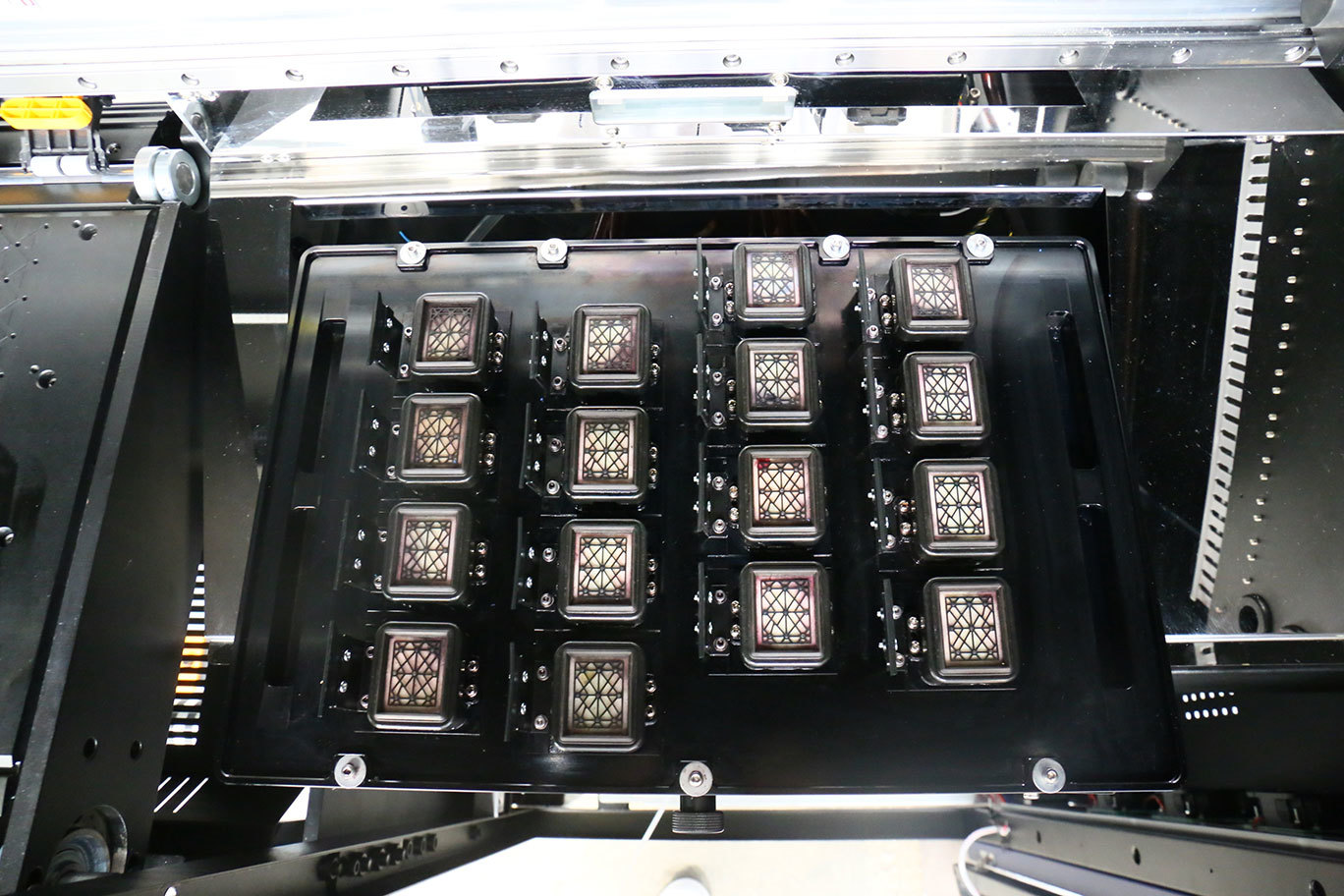

·Using 16 Epson I3200-A1 print heads, combined with variable droplet technology, the droplet precision reaches 3.5 - 18 pl, enabling an impressive 98% color reproduction accuracy. The patterns are fine and the transitions are natural.

· Equipped with an automatic cleaning + flash spray moisture retention dual system, it significantly reduces the risk of print head blockage, and the maintenance interval is extended to 480 hours, ensuring continuous and stable output of high-quality images.

Part.2 Industrial-grade speed, with a significant increase in production capacity

·The printing speed can reach up to 670㎡/h, which is 40% higher than the industry average. With two shifts working, the daily output can easily exceed 10,000 meters, enabling rapid response to large-scale order demands.

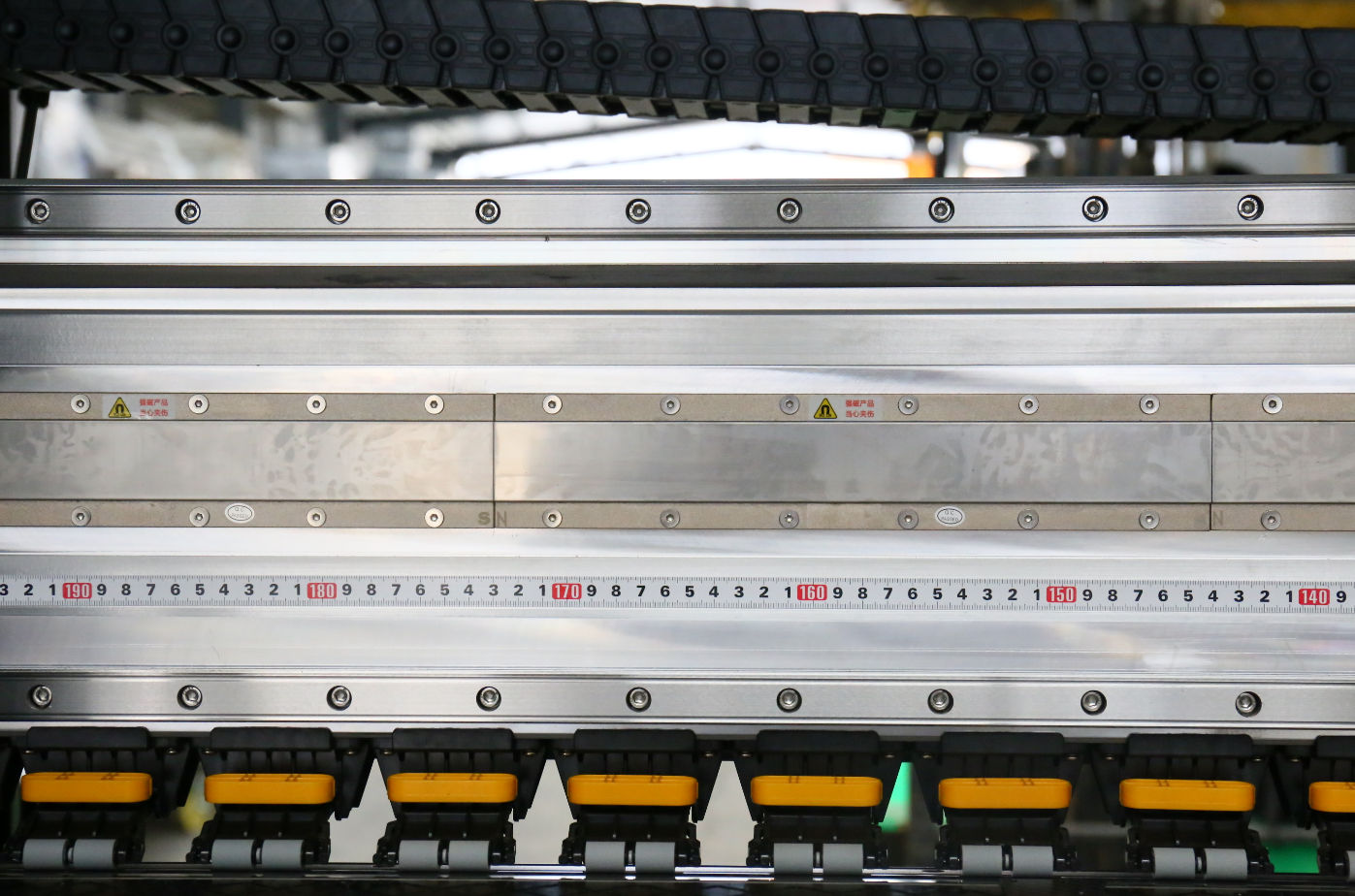

·Magnetic levitation linear motor + THK ultra-quiet guide rail combination, with a positioning accuracy of ±0.01mm, a speed fluctuation of less than 2%, maintaining high-speed performance without degradation, and running more quietly.

Part.3 Steady as a rock, continuously operating without any downtime

·An integrated steel structure frame with a vibration amplitude controlled within 0.03mm, ensuring no offset during long-term printing.

·The air expansion belt constant tension system can bear a load of up to 500kg, with a paper deviation rate of less than 0.1%, and the rolled material printing is also flat and stable.

·The industrial servo motor drives the winding and unwinding process, with a response time of only 0.05 seconds and precise and sensitive tension control.

Part.4 Intelligent maintenance, saving you both time and effort

· A visual print head monitoring interface is provided, allowing you to clearly see the status of all 16 print heads at a glance and receive early warnings for any malfunctions.

· 15L Central Ink Supply System supports 72-hour continuous printing. It automatically alerts when ink is low and ensures uninterrupted printing even when the ink runs out.

· The modular ink path design reduces maintenance and replacement time by 60%, significantly enhancing equipment utilization rate.

The FEDAR FD61916E digital printing machine is not merely a piece of equipment; it is also a valuable ally for enhancing your production efficiency and quality control. Whether it is for printing on clothing fabrics, home textiles, or advertising posters and decorative materials, it can perform efficiently, stably and intelligently, enabling you to easily handle large-scale orders and gain market competitiveness.

Keyword:

sublimation printer,FEDAR,digital printer,textile printer,tshirt printer

RECENT POSTS