White Ink Direct-to-Film Transfer (DTF): Introduction and Practical Applications

Release time:

2025-06-18

Working principle and operation procedure

1. Pattern Design and Processing: Firstly, use professional graphic design software such as Adobe Illustrator, CorelDRAW, etc. to create the pattern design. After completion, save the pattern in common and suitable file formats for printing, such as PDF, JPEG, PNG, etc. Then, use printing software (RIIN, Flexiprint, CADlink, Maintop, etc.) to pre-process the pattern, adjusting parameters such as size and resolution to ensure that the pattern meets the printing requirements.

2. Printing Process: Insert the white ink and CMYK colored inks into the dedicated printer that supports DTF printing. Place the PET release film into the printer. Based on the complexity of the pattern, the richness of colors, as well as the characteristics of the PET release film and the substrate, precisely set the printing parameters in the printer driver, such as nozzle temperature, printing speed, ink volume, etc. After the settings are completed, the printer will follow the instructions, first spray white ink on the PET release film to form the white part or the base layer of the pattern, and then spray CMYK colored ink to create the complete pattern.

3. Spraying and Baking: After printing the pattern on the PET release film, it is necessary to quickly and evenly sprinkle hot melt adhesive powder over the entire white ink layer of the pattern. This operation can be achieved through the automatic shaking function of the powder shaker, which is more efficient and results in a more uniform powder distribution. After the powder is sprayed, use the built-in drying function of the AGP white ink transfer printer or a dedicated baking equipment to bake it at an appropriate temperature (generally 120℃ - 150℃), allowing the hot melt adhesive powder to melt under heat and blend with the ink, achieving solidification and formation.

4. Transfer Step: Place the fabric to be heat-pressed, such as pure cotton T-shirts, denim, canvas bags, etc., flatly on the platform of the heat press machine. Place the PET release film with the pattern facing down precisely over the fabric. Start the heat press machine and set the appropriate temperature (usually 150°C - 180°C), pressure (about 5 kg/cm²), and time (approximately 8 - 15 seconds) according to the fabric material to perform the heat pressing. After completion, depending on the type of PET release film, choose hot removal (removing the release film directly at high temperature) or cold removal (removing the release film after cooling), at which point the pattern has been successfully transferred onto the fabric.

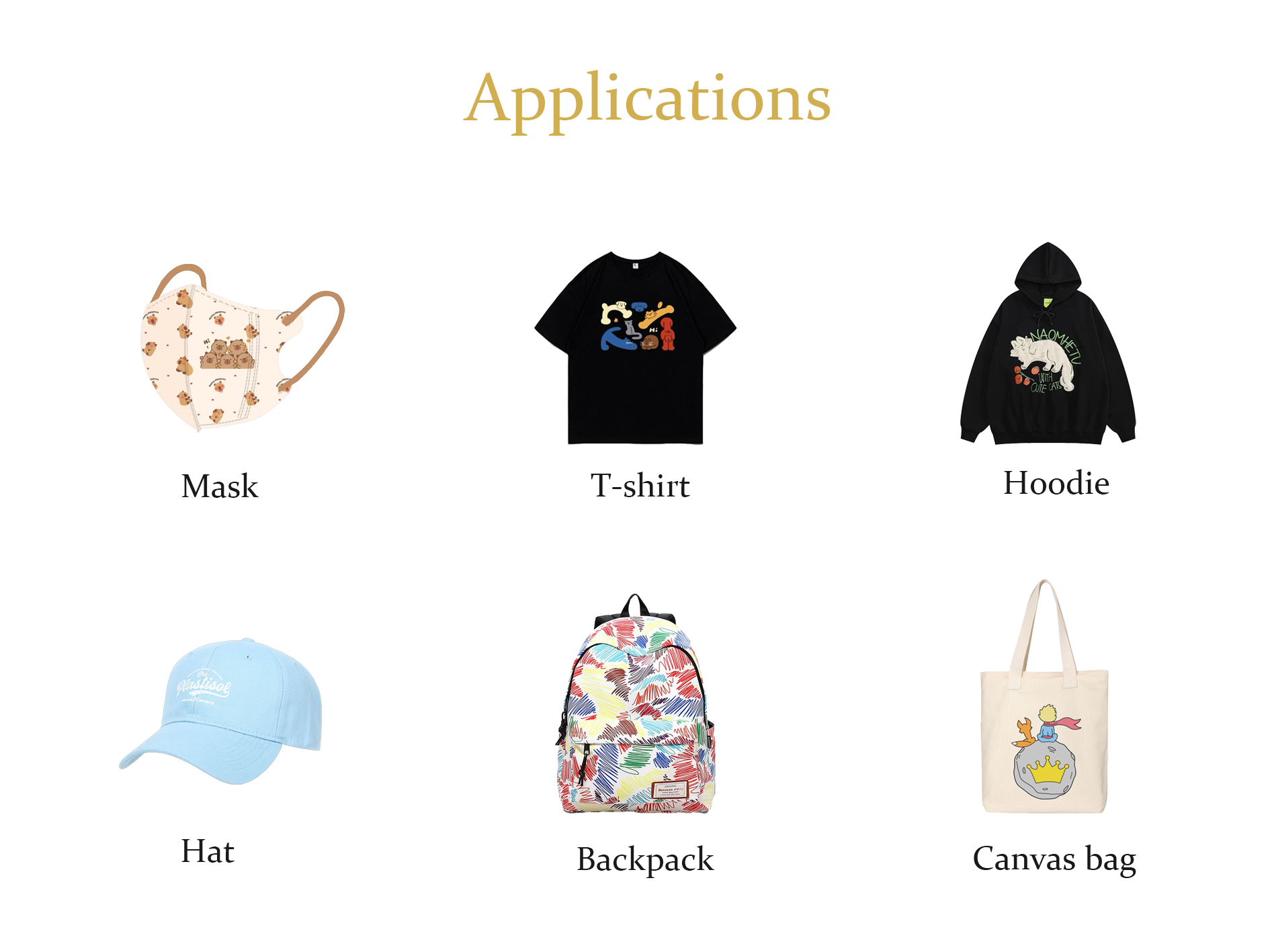

Application scenario

1. Fashion industry: Printing brand logos, trendy patterns, and personalized slogans on various types of clothing such as T-shirts, sweatshirts, sportswear, and children's clothing to add unique design elements and enhance product value and brand recognition.

2. Bag sector: Applying exquisite patterns and brand logos on the surfaces of bags like backpacks, handbags, and wallets to make the bags more fashionable and distinctive.

3. Shoe decoration: Printing unique patterns on the surfaces of sports shoes, casual shoes, and canvas shoes to create one-of-a-kind shoe styles and meet consumers' personalized needs.

4. Home textiles: Such as throw pillows, curtains, and bedding items, using DTF white ink heat transfer printing to print creative patterns to enhance the aesthetic appeal and personalized style of home soft furnishings.

5. Promotional gifts and souvenirs: Producing promotional gifts with the company logo and event theme, or cultural shirts, badges, and other commemorative items with cultural significance, to serve as promotional tools and for memory preservation.

Keyword: