The key steps for perfect maintenance of Epson print heads

Release time:

2025-06-25

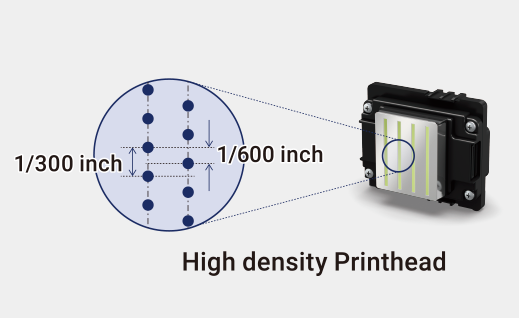

Epson print heads can be applied to printers such as white ink heat transfer printers, crystal label printers, and white ink direct inkjet printers, and are suitable for water-based inks, UV inks, and weak solvent inks. Moreover, the print nozzle resolution of Epson print heads is as high as 600dpi, and one print head can achieve 4-color printing at most. And the 3200 print head of Epson is currently one of the most favored print heads by manufacturers.

The print head of Epson 3200 is not large in size, approximately 7cm * 6cm * 3.5cm. However, it is composed of 3200 printing holes, which are very precise components. Therefore, the price of Epson 3200 print head is also quite high. As a result, after purchasing the Epson 3200 print head, all major manufacturers must maintain it professionally and carefully.

Firstly, when installing the sprinkler head, the wiring on both sides should be covered with special adhesive tape to prevent water from entering the wiring port and damaging the sprinkler head. This detail must be paid attention to during installation! It is extremely important! If your white ink transfer printer or other machines are working every day, a simple maintenance should be carried out once a day.

Before shutting down the machine after each day's work, move the printing carriage to the left, and use the special cotton cloth to wipe the ink stains on the surface of the print head to keep the print hole clean and free of debris. Then, move it back to the top of the ink pad.

Before shutting down and after starting up the machine every day, it is necessary to clean the print head and print a test strip to check the status of the print head. The test strip should show that the ink flows smoothly and continuously to be able to shut down or start the daily printing work.

If the white ink transfer printer or other machines you use have a relatively low working frequency, you should also perform regular maintenance. Because from the moment the Epson print head is filled with ink, it needs to remain moist and cannot dry out. If the print head is not used for a long time, the ink inside it will dry up and clog the print head. Therefore, regular maintenance is extremely necessary.

Keep printing twice a week. The amount of printing does not need to be too large. The purpose is to keep the ink in the print head flowing smoothly and moist, avoiding drying and hardening.If the printhead has not been used for a long time, then a moisturizing solution should be applied to the printhead first for moisturization, and then the machine can be turned on to allow the ink to flow and print.

In addition to maintaining the print head itself, the maintenance of the ink pad is also very important. The ink pad and the print head are integrated and inseparable. The ink pad also needs to remain moist at all times to effectively seal and moisturize the print head. Therefore, when maintaining the print head, all manufacturers should not neglect the maintenance of the ink pad either.

Finally, whether it is a white ink heat transfer printer, a crystal label printer, or a white ink heat transfer direct printer, regular comprehensive machine inspections are necessary. Daily maintenance combined with regular checks can ensure that the machine is in the best condition and can produce the best products.

Keyword: