Maintenance Tips for DTF White Ink Heat Transfer Printers

Release time:

2025-08-16

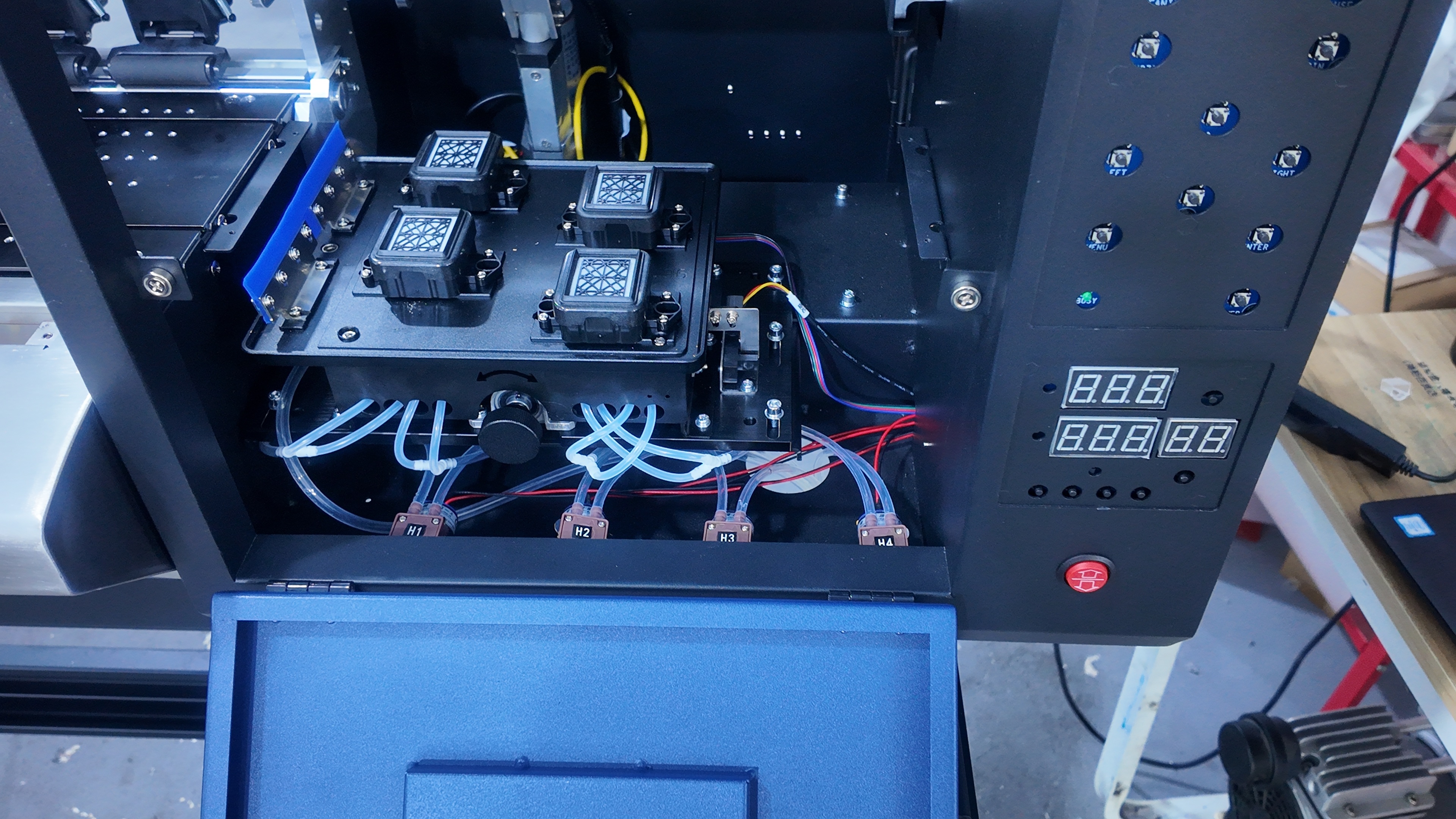

The daily maintenance of DTF white ink heat transfer printers is crucial for maintaining print quality and extending the lifespan of the equipment. Especially given the characteristic of white ink being prone to sedimentation, targeted maintenance is even more necessary. The following are the key points for daily maintenance:

I. Daily Startup Check

1. Appearance and Environment Check

Ensure the printer is placed stably, with no dust, oil stains, or water marks around it. Avoid direct sunlight or humid environments (the humidity is recommended to be maintained at 40% - 60%).

Check if the power and data cables are securely connected without any looseness or damage.

2. Ink System Check

Observe if the white ink bottle is full to prevent air from entering the pipeline due to an empty bottle.

Check for any kinks, blockages, or ink leakage in the ink tubes, especially the white ink tube which is prone to blockage due to sedimentation.

II. Pre-print Maintenance

1.White Ink Stirring

After turning on the machine, it is essential to execute the "White Ink Stirring" procedure (the specific operation varies depending on the model; usually it can be selected in the settings). The recommended stirring time is 5 to 10 minutes to ensure that the white ink particles are evenly suspended and to prevent clogging. If the machine has not been used for a long time (more than 24 hours), it is recommended to stir twice, with an interval of 10 minutes.

2.Print Head Cleaning and Testing

Perform the "Print Head Cleaning" (preferably choose "Light Cleaning" to avoid excessive ink consumption), and then print the "Print Jet Inspection Pattern".

If the pattern shows broken lines or color deficiencies, it is necessary to clean the corresponding color print head specifically until the lines are complete (the white ink print head needs to be checked particularly as its particles are larger and more prone to clogging).

III. Precautions during Printing Process

1.Avoid prolonged downtime

If printing is interrupted halfway (for more than 30 minutes), you need to manually activate the "Print Head Moisture Retention" function or print a test page to prevent the white ink from settling and drying out at the print head.

During continuous printing, check the ink tube pressure every 2-3 hours to ensure smooth ink delivery.

2.Material and Environment Control

Keep the printing platform clean to prevent dust and paper debris from adhering to the nozzle or the materials, which could cause scratches on the printing head.

White ink printing is temperature-sensitive. It is recommended that the environmental temperature be between 20 and 25 degrees Celsius. If the temperature is too low, it will cause the ink to have poor fluidity, thereby affecting the adhesion.

IV. Daily Maintenance After Shutting Down the Printer

1.Print Head Protection

Execute the "Print Head Return" procedure to bring the print head back to the moisturizing seat, ensuring proper sealing and moisturization, and preventing ink from drying out.

If the printer is not used the next day, add a small amount of dedicated moisturizing liquid to the moisturizing seat (avoid using plain water to prevent ink dilution and deterioration).

2.Equipment Cleaning

Dip a lint-free cloth in a small amount of alcohol and wipe the surface of the print head, the print platform, and the paper feed roller to remove residual ink and dust (note: when wiping the print head, do it gently to avoid touching the print nozzle).

Clean the waste ink in the ink receiving tray to prevent overflow from contaminating the equipment or breeding bacteria.

3.White Ink Pipe Maintenance

If the printing volume for the day is low, manually return the ink in the white ink pipe to the ink bottle (some models support this function). Reduce the standing time of the ink in the pipe; before starting the printer the next day, re-pump the ink and release the air.

V. Weekly Deep Maintenance

1.Check of ink cartridge and filter

Check if there is any residue of ink in the white ink cartridge. If there are obvious particles on the inner wall, disassemble and clean or replace (it is recommended to replace the white ink filter once a month to prevent impurities from entering the printing head).

2.Lubrication of guide rails and belt

Lightly apply the special lubricant (such as sewing oil) to the guide rails, and wipe off the excess grease with a dust-free cloth to ensure smooth movement of the print head carriage; check the tightness of the synchronous belt, which should be neither too loose nor too tight, as too loose a belt may cause printing misalignment.

3.Cleaning of waste ink storage

Open the side cover of the equipment, remove the waste ink storage, pour out the waste ink and clean it (use clean water for rinsing and then dry it), to avoid the waste ink overflowing and damaging the main board.

Through the above daily maintenance, the failure rate of the white ink transfer printer can be significantly reduced, ensuring stable printing results (such as white ink coverage and color reproduction accuracy), and prolonging the service life of core components like the nozzles (high-quality nozzles have a higher price and can be used for 6-12 months with proper maintenance). It is recommended to establish a maintenance record sheet, regularly record the maintenance time and content, which will facilitate problem tracing.

Keyword: