1. Anti-collision Cart Stabilizer Frame: It can adjust the height of the spray head flexibly according to different printing consumables, has wide application range and is convenient to adjust; additional anti-collision devices are added at both ends to provide more comprehensive safety protection for the spray head.

- Inquiry

PRODUCTS

XINRUNCAI

Sublimation Printer 8PCS printhead Machine

- Name: Sublimation Printer 8PCS printhead Machine

- Commodity ID: S-002

- Deposit: 38000

- Price: 125000(Excluding tax)

- Quantity: Purchase limit of 5 units

- Return time: 24 hours/48 hours/72 hours/customized

WeApp:18664690156/18150562320

WeChat:Allanhuping / XRCSMKJ

Email:sale1@xinrundtf.com / sale2@xinrundtf.com

Tel: 086+19396091132 / 086+18150562320 / 086+18620867604

Email:sale2@xinrundtf.com

Online inquiry

Detailed Introduction

Functions and Features

Product parameters

Model | FD6198E |

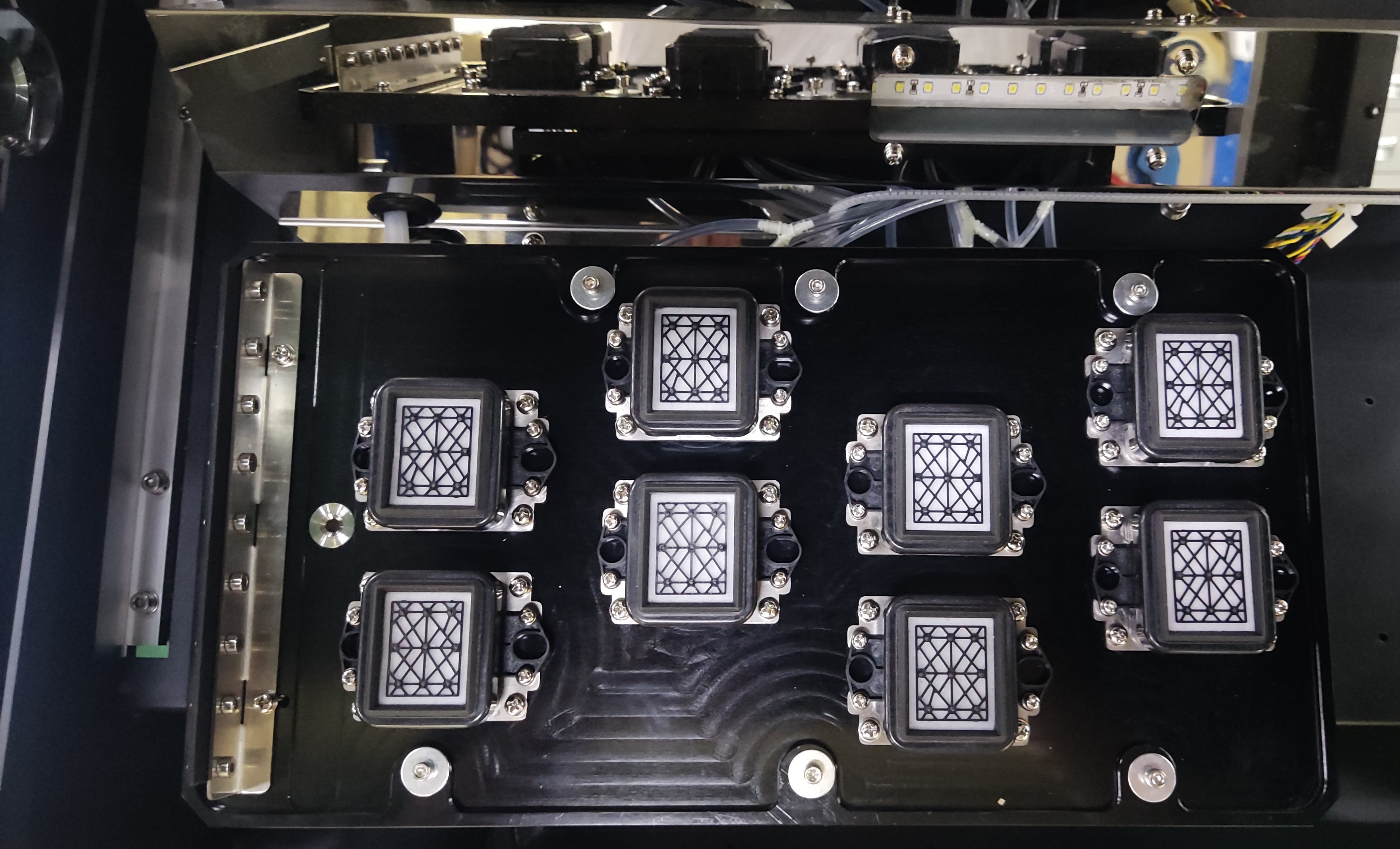

Printhead | Type: Epson I3200-A1 printhead, Quantity of printing nozzle: 3200PCS, Attributes: automatic cleaning, spraying, and moisturizing functions |

Quantity of Printhead | 8 PCS |

Print Speed | V360V1200dpi 1pass 370m²/h, V360V2400dpi 2pass 185m²/h |

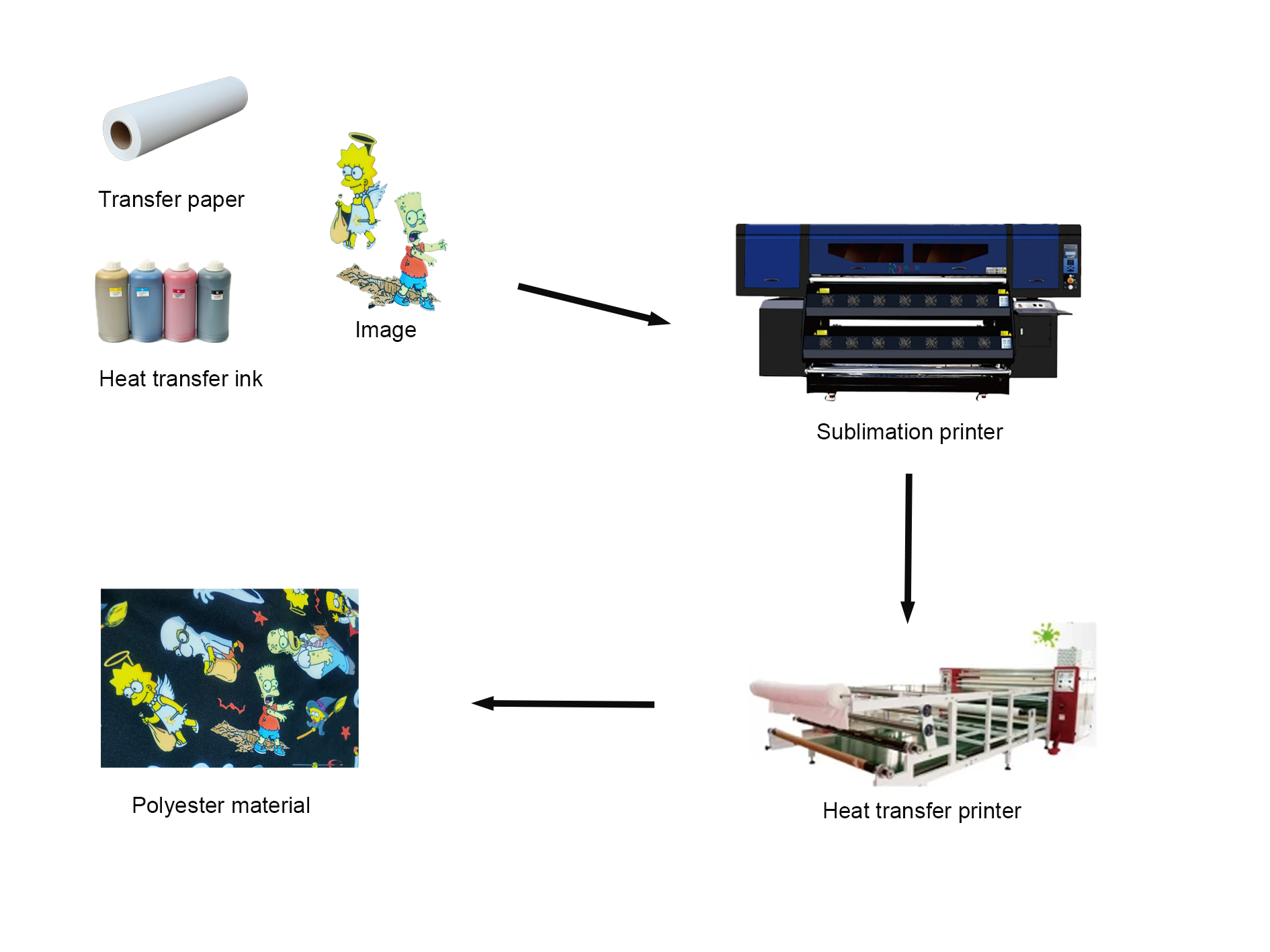

Ink Type | Type: Sublimation ink, Color: CYMK |

Effective Width | 1900mm |

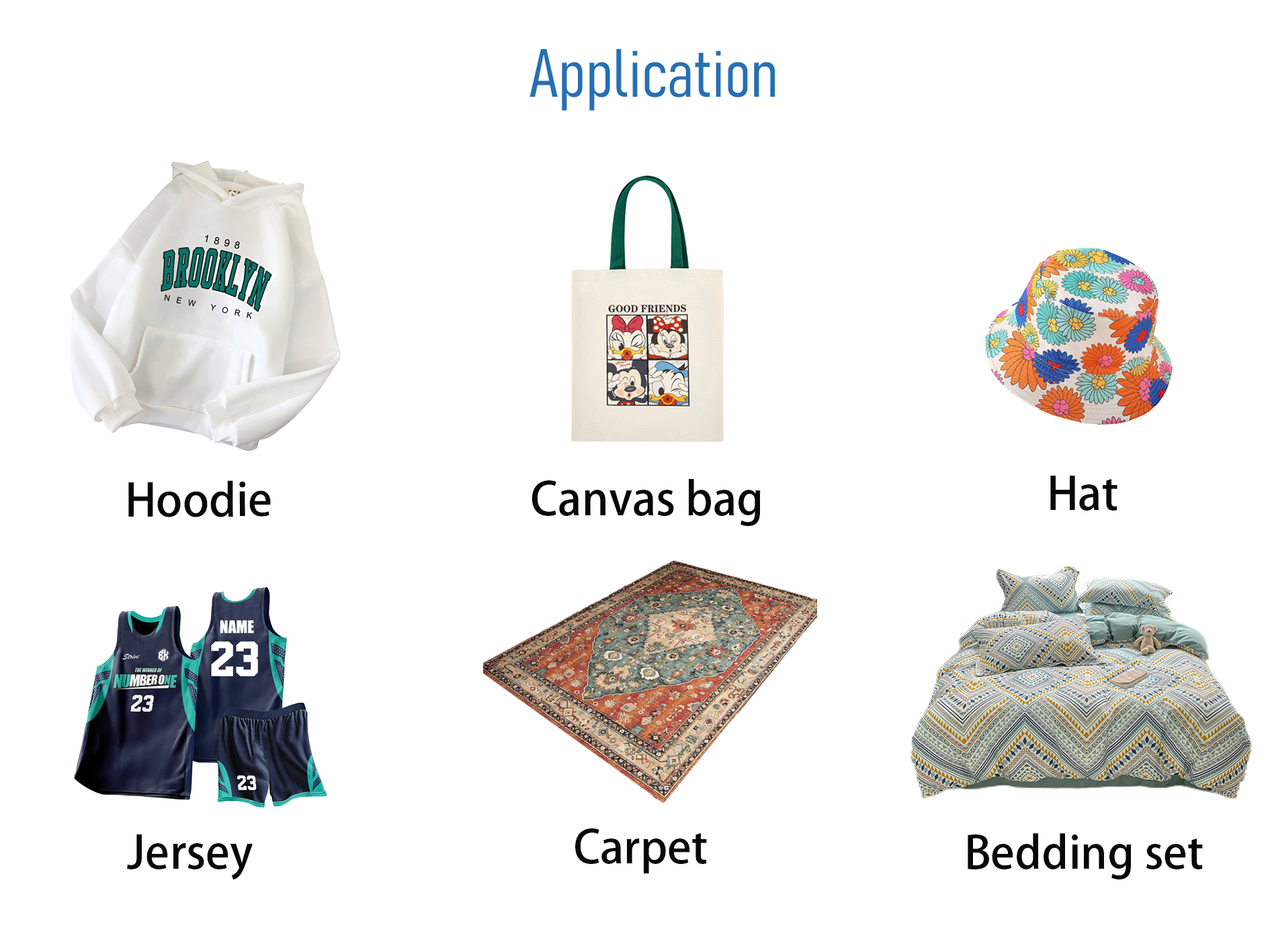

Print Medium | Heat transfer paper |

Transmission Medium | Retractable air shaft system |

Drying Methods | External intelligent air-heat integrated dryer |

Moisturizing Mode | Fully sealed automatic moisturizing and cleaning |

RIP Software | Applicable to Maintop6.0, PhotoPrint, ONYX, NeoStampa and other software; Standard configuration: Maintop6.0 |

Picture Format | JPG, TIF, PDF, etc. |

System Configuration | Operation system: Win7 64-bit, Win10 64-bit; Hard disk: 500G or more (SSD recommended); RAM: 8G; Graphics card: ATI 4G; CPU: i7 processor; Transmission interface: GigE port |

Standard Configuration | Tension delivery system, intelligent drying system, liquid level alarm system |

Working Environment | Temperature: 18°C-30°C, Humidity: 35%-65% |

Power Supply | Input voltage: 210-230VAC 50/60HZ 16A, Printing system: 1500W, Drying system max power: 7200W |

Machine Size | External size: 3710*1500*1940mm, Package size: 3900*1340*1980mm |

| FD6198E 8-head 1.9m |

| It features industrial-grade panel frame structure, intelligent asynchronous retracting control system, THK20 double guide design, self-developed air draft platform, intelligent drying system and automatic start and stop function, with a 1.5L ink box which can achieves liquid level monitoring and alamm. lt is equipped with 8 Epson original certified I3200-A1 printheads, with a minimum ink droplet of 2.5pl, printing accuracy and speed increased by more than 20% and 30%. | |

| FD61915E 15-head 1.9m |

| It features automatic cleaning, spraying and moisturizing functions, and it canachieve fully sealed automatic moisturizing and cleaning of retracting system for air shaft. lt is equipped with external intelligent air-heat dryer, tension deliverysystem,intelligent drying system and liquid level alarm system. |

Keyword:

Machinery Equipment

printhead

ink

heat transfer printer

Industrial-grade high-end digital printer

Online Inquiry

Please leave your correct information, we will contact you as soon as possible