FD6198E is custom processed, easily meeting your requirements!

Release time:

2025-09-17

This 8-head digital printing machine of FEDAR - FD6198E. It is extremely suitable for small batch customization, especially for e-commerce processing.

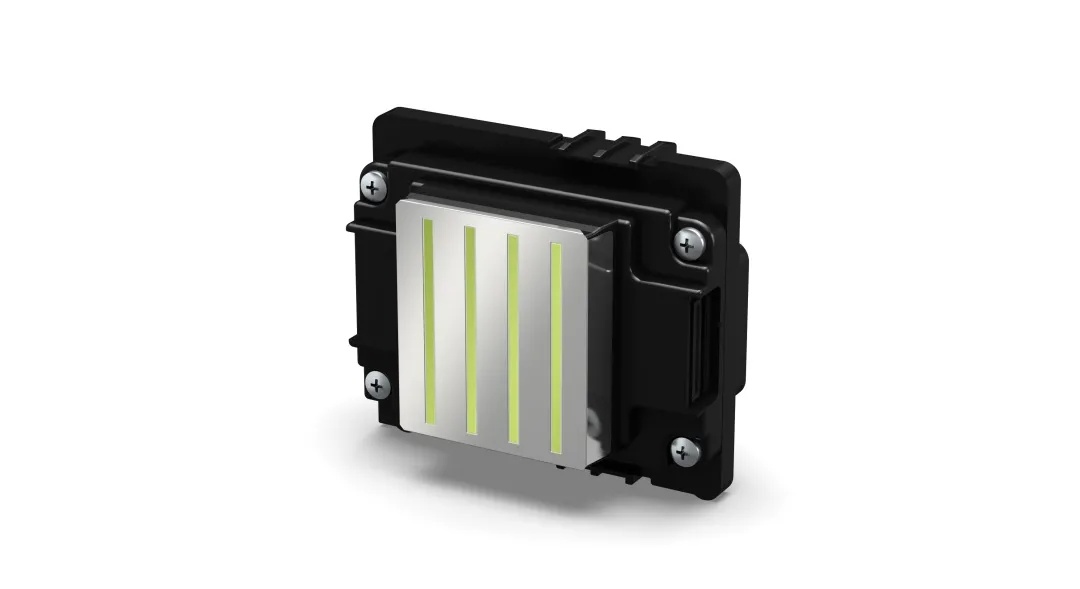

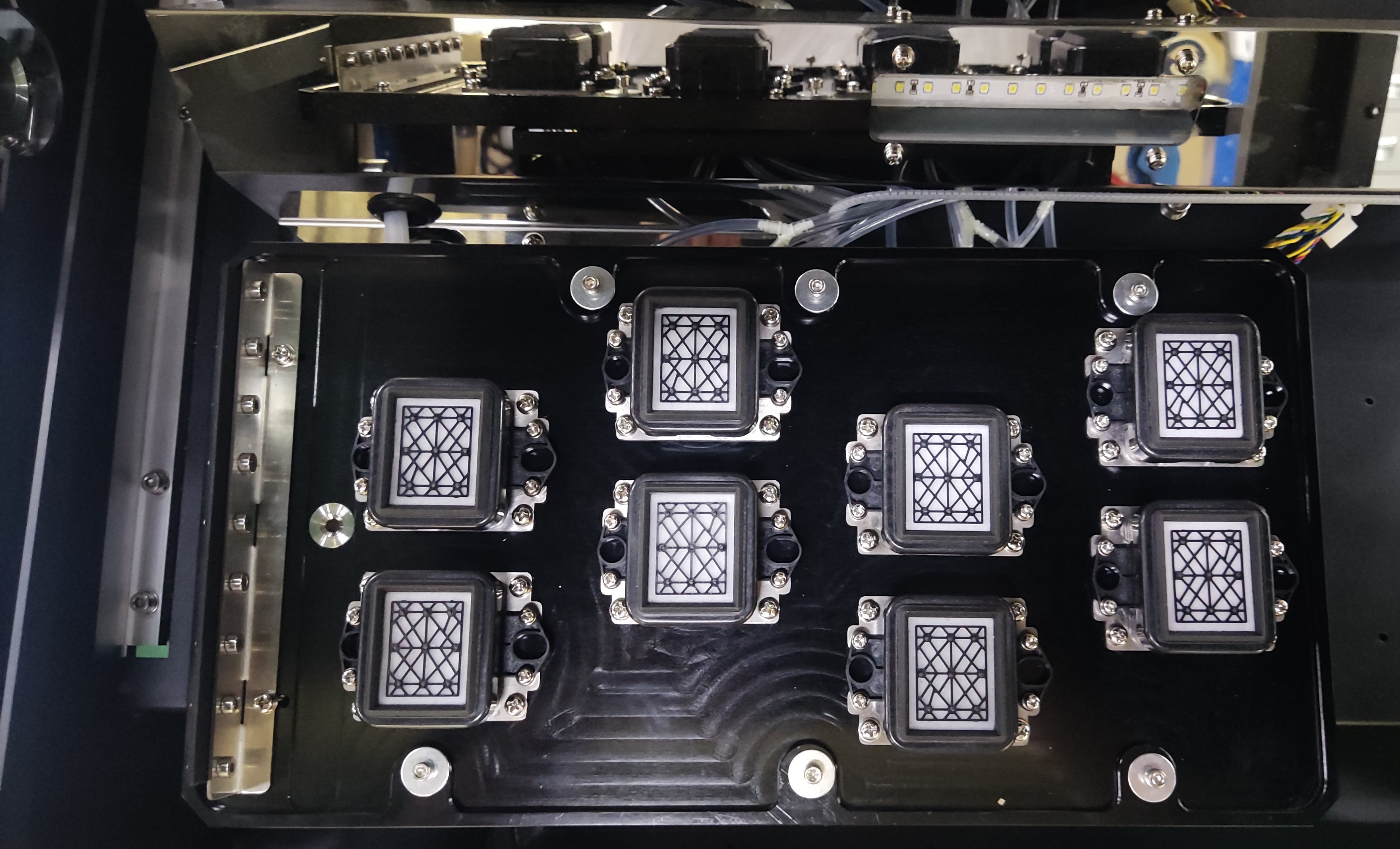

(1) This machine is equipped with 8 Epson I3200-A1 inkjet heads, capable of producing 370 square meters per hour at high speed. Each head has 3,200 inkjet nozzles. The ALL MEMS (Micro-Electro-Mechanical System) manufacturing process and the use of thin-film piezoelectric components enable the realization of high-precision nozzle arrangement (600 npi/2 rows), resulting in a compact printing head structure, high speed, good quality and durability. In addition, Epson's unique VSDT (Variable Drop Size Technology) can freely control the size of the ink droplets sprayed, thereby reducing the graininess of the image, presenting more image details, smooth color transitions and high saturation.

(2) Anti-collision Cart Frame: It can adjust the height of the nozzle flexibly according to different printing materials, has wide applications and is easy to adjust; additional anti-collision devices are added at both ends to provide more comprehensive safety protection for the nozzle.

(3) Advanced nozzle intelligent cleaning and moisturizing device: This provides a safe and convenient cleaning and maintenance function for the printing nozzles, making the operation and maintenance process much more convenient.

(4) Imported fluororubber paper pressing wheels from the United States: Prevent static electricity from causing ink to fly, ensuring more accurate printing dimensions; The unique lifting mechanism for the paper pressing wheel can be adjusted at any time to deal with the phenomenon of local paper bulging during the printing process.

(5) Japanese THK silent linear guide rail: Smooth movement, longer lifespan, and it can effectively reduce the resistance and noise during the operation of the ink carriage in high-speed motion.

(6) Air-inflated shaft type reel-up/reel-down system: During operation, there is no need to fix the printing medium with any additional accessories. By utilizing the pressure of air, it automatically adjusts to ensure uniform force distribution and smoother paper feeding. This reel-up/reel-down system features a large load-bearing capacity, long service life, uniform force distribution during reel-up/reel-down operations, and short charging and discharging operation times.

(7) Damping rubber strip paper expansion device: Ensures the paper is neatly and tightly rolled, making the operation more convenient.

The ink usage of FD6198E-A is "automatically allocated" by the computer, eliminating the waste of dyes and environmental pollution problems. The entire process is controlled by the computer, which is easy to operate and convenient to use. One person can simultaneously monitor and operate multiple machines, significantly reducing labor costs.

Keyword: