Exploring the three core advantages of printing with DTG printers

Release time:

2025-10-23

The DTG (Direct-to-Garment) printer offers advantages across multiple aspects, as detailed below:

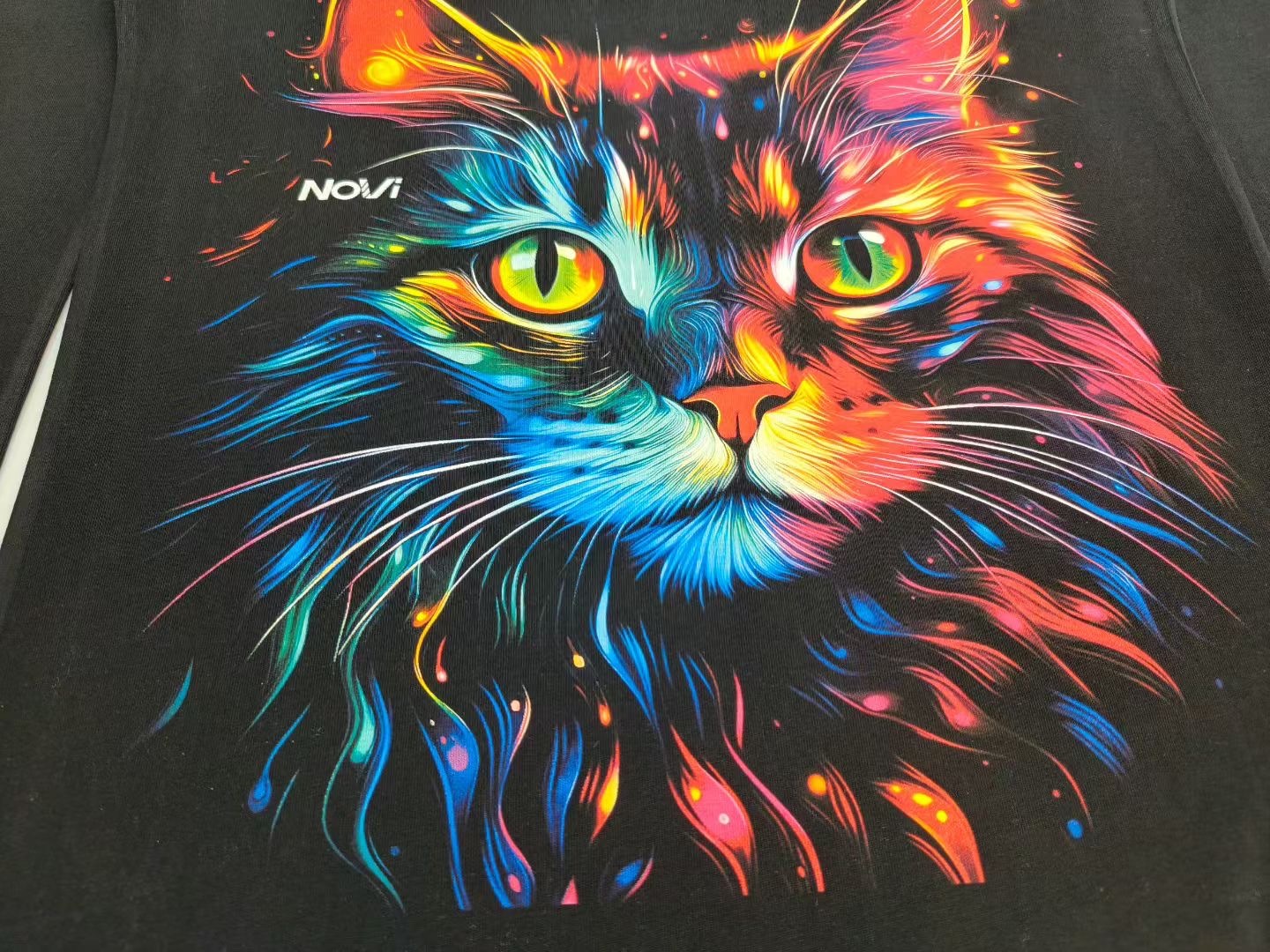

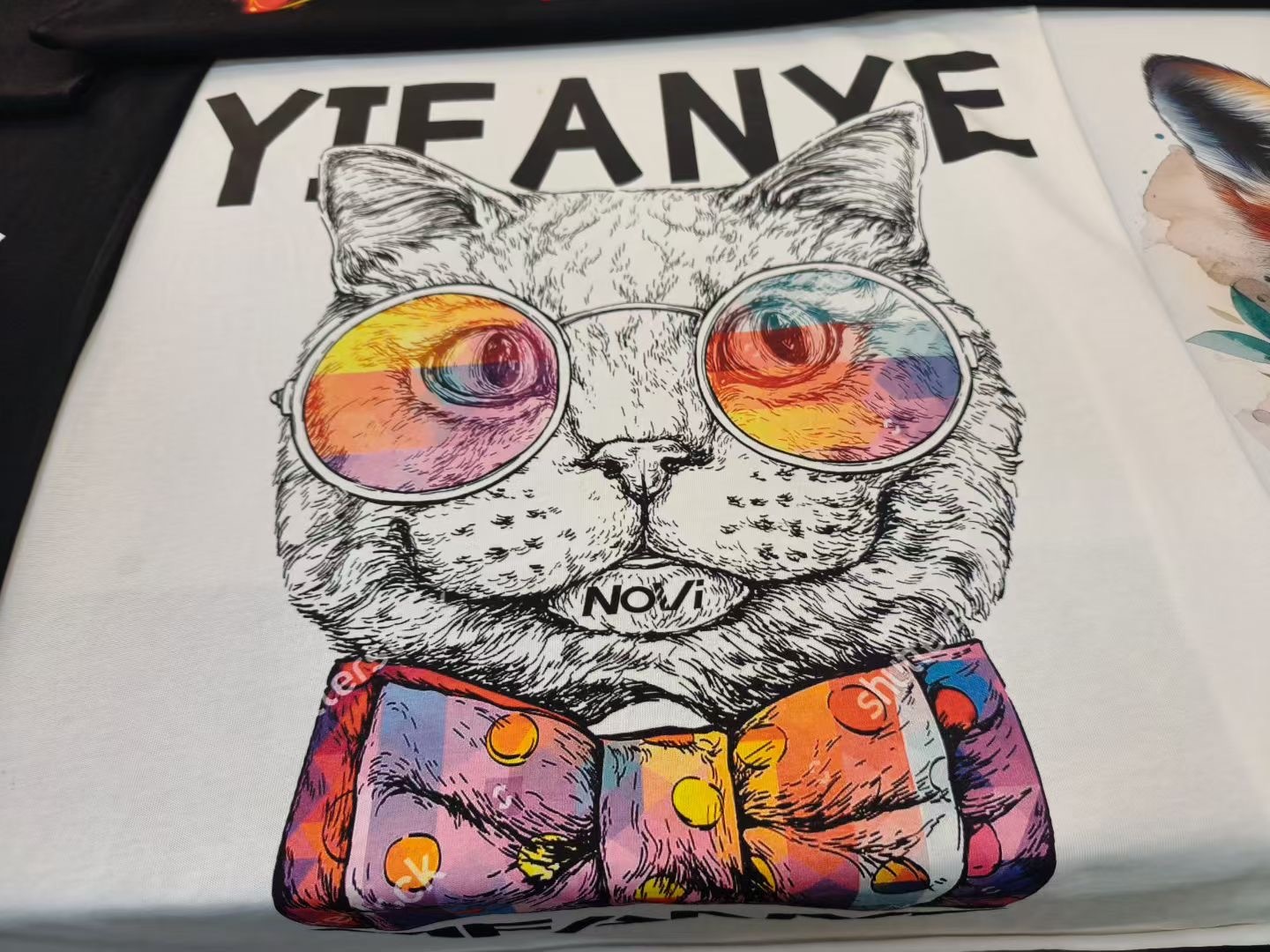

High Pattern Quality

Clear Details: DTG technology uses high-precision printheads, which can accurately reproduce fine lines, gradient effects, and complex textures in patterns. It supports photo-level detail reproduction, far exceeding the resolution limits of traditional screen printing.

Rich Colors: It supports CMYK four-color and white inks, capable of mixing millions of colors with natural color transitions. This meets the demand for special colors such as high saturation and low lightness in personalized designs.

No Screen Restrictions: Unlike screen printing, it does not require screen production, eliminating the screen-induced limitations on color layers. It is especially suitable for patterns with multiple colors, gradients, and strong light-shadow effects.

High Production Efficiency

Flexible Minimum Order Quantity: DTG printing requires no plate making, enabling single-piece production. The cost difference between small orders of multiple pieces is minimal, making it ideal for needs like "one garment per person" and "small-batch customization"—such as team uniforms, event commemorative shirts, and personal streetwear brands.

Short Production Cycle: From transferring the design file to completing the print, the process usually takes only a few minutes. There is no need to wait for screen production and color mixing, significantly shortening the production cycle and allowing quick response to order demands.

Fast Re-printing: If re-printing of the same pattern is needed, DTG printers can do it quickly and easily, saving time and costs.

Easy Operation

Reduced Labor and Training Needs: DTG printing technology replaces expensive labor and lengthy skill training with technology. A single person can handle all tasks from order receiving and printing to delivery preparation, without the need for a large number of skilled workers.

Simple Equipment Setup: The setup of DTG printers is relatively simple, and they occupy small space. No complex installation and debugging processes are required, making them suitable for enterprises of all sizes.

Wide Application Range

Strong Fabric Compatibility: It is not only applicable to natural fabrics such as pure cotton and cotton blends but also can stably print on regenerated cellulose fabrics like bamboo fiber and modal. Some improved equipment can even handle fabrics containing a small amount of chemical fibers.

Flexible Printing Positions: It can print on various parts of clothing, including hard-to-print areas like zippers and pockets, achieving seamless printing.

Good Environmental Performance

Eco-friendly Inks: Mainstream DTG inks adopt water-based formulas, which do not contain harmful substances such as formaldehyde and heavy metals. They meet international environmental standards like OEKO-TEX, causing little impact on human health and the environment.

Waste Reduction: Unlike traditional printing, it does not require screen cleaning, reducing wastewater discharge. Moreover, it enables on-demand printing, avoiding fabric and dye waste caused by overproduction.

Keyword: