Manual Heat Press Machine: A Cost-Effective Choice for Small-Batch Production and Entrepreneurship

Release time:

2025-10-31

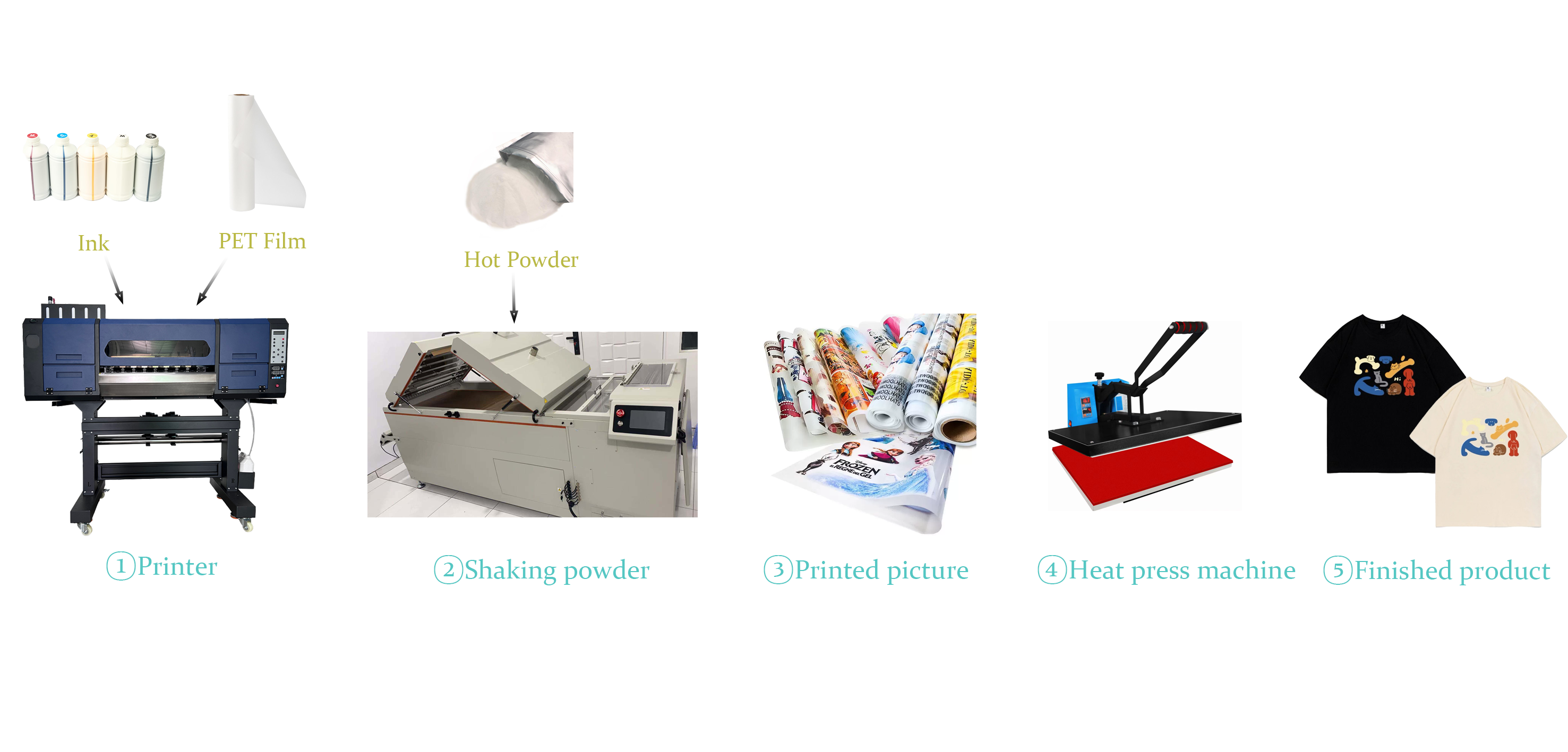

In the current era where the demand for personalized customization is growing, heat press machines have become key equipment for pattern printing in industries such as clothing and home accessories. Among them, manual heat press machines, with their flexibility and cost-effectiveness, have emerged as an ideal choice for small-batch production businesses, entrepreneurial teams, and handcraft enthusiasts. They do not require complex automated devices; instead, they can complete high-quality heat transfer work by manually adjusting temperature, pressure, and time, thus occupying an irreplaceable position in the niche market.

The core advantage of manual heat press machines first lies in their cost-friendly feature, which greatly lowers the entry barrier. In terms of equipment procurement, their structure is relatively simple, without the need for complex automated control systems, so their selling price is much lower than that of semi-automatic or fully automatic heat press machines. For start-up teams, personal studios, or small businesses, this can effectively reduce the initial capital pressure. During subsequent use, the maintenance cost is also manageable - with fewer mechanical components and an intuitive operating principle, daily maintenance only requires cleaning the heat transfer panel and checking the circuit connections. Complex malfunctions rarely occur, which not only saves maintenance costs but also avoids production delays caused by equipment downtime. In addition, they have extremely low requirements for the site. Most models are compact in size (with a common size of approximately 60cm × 50cm × 40cm), and no dedicated large-scale operating space is needed. They can be easily placed in a corner of a home or a small studio, further reducing operating costs.

Secondly, the flexible adaptability of manual heat press machines enables them to meet diverse production needs, especially suitable for small-batch and personalized orders. In terms of heat transfer materials, they have strong compatibility. They can not only handle common cotton and polyester fabrics (such as T-shirts and sweaters) but also adapt to canvas (school bags, canvas bags), leather (wallets, notebook covers), knitted fabrics (hats, scarves), and more. There is no need to frequently replace molds or accessories; only temperature and time parameters need to be adjusted according to the material. For small-batch orders, they are even more of a "high-efficiency tool" - fully automatic heat press machines often require pre-adjustment of the mold and setting of batch parameters, making them more suitable for large-scale production of over 100 pieces. In contrast, manual heat press machines do not require a complex preheating process. When receiving small orders of 10 or 20 pieces, operators can quickly start working. They not only ensure the accuracy of patterns but also avoid resource waste due to "considering small orders as too few". At the same time, the flexibility in parameter adjustment makes personalized customization easier to achieve: different heat transfer papers (such as thermal transfer paper, offset heat transfer paper, and luminous heat transfer paper) have different requirements for temperature and pressure. Manual models allow for intuitive parameter adjustment through knobs or buttons. Whether printing delicate cartoon patterns, personalized text, or heat transfers with special effects, precise control can be achieved to meet customers' customized needs.

Furthermore, the easy-to-learn operation threshold allows more people to quickly master the usage skills. Unlike industrial-grade fully automatic equipment that requires professional training, the operation process of manual heat press machines is simple and intuitive: you only need to lay the item to be heat-transferred flat on the workbench, align the pattern position, press down the heat transfer head, set the time, and lift the heat transfer head after the time is up to complete the work. Even beginners without experience can usually become familiar with the basic operations within 1-2 hours by reading the instruction manual or watching a few minutes of tutorial videos, and can independently complete stable production within 1-2 days. There is no need to invest additional time and energy in learning complex equipment operation knowledge, which greatly shortens the cycle from "equipment acquisition to product output".

Of course, when choosing a manual heat press machine, it is also necessary to pay attention to key parameters based on one's own needs to ensure that the equipment is suitable for the production scenario. Firstly, consider the heat transfer area, which should be selected according to the size of the main products. If the main products are T-shirts and sweaters, it is recommended to choose a heat transfer panel of 38cm × 38cm or 40cm × 50cm to meet the heat transfer needs of most clothing items. If the focus is on small items (such as hats and wallets), you can choose a model with a small panel or match it with dedicated accessories (such as a hat heat transfer fixture). Secondly, pay attention to heating uniformity. High-quality models use cast aluminum for the heat transfer panel, with evenly distributed heating tubes, which can avoid pattern blurring or peeling caused by local temperature differences. When purchasing, you can check the product parameters or consult the merchant to see if there is a heating uniformity test report. Finally, look at the pressure adjustment method. Most manual models adjust pressure through a knob. It is recommended to choose a product with a wide pressure range and smooth adjustment to ensure that materials of different thicknesses (such as thick sweaters and thin T-shirts) can obtain appropriate pressure, thus ensuring the firmness of the heat transfer.

For users who pursue cost-effectiveness and focus on small-batch personalized production, manual heat press machines are not just a piece of equipment, but a "capable assistant" that reduces entrepreneurial risks and responds flexibly to market demands. Whether it is building a personal brand's customized T-shirt studio or providing small-batch heat transfer services for canvas bags and hats to surrounding businesses, manual heat press machines can help users start quickly and develop steadily in the personalized customization market with their advantages of low cost and high flexibility.

Keyword:

dtf,dtf printer,DTFPrinting ,DTFTransfers,TShirtPrinting,TransferPrinting,PrintingServices